| Mtundu wa kalasi yachitsulo | Chitsulo cha nkhungu: |

| Muyezo |

|

| Mafotokozedwe a kupanga | Mbale yachitsulo, Mapepala, Chophimba, Mzere Wosalala, Mzere wozungulira, Chitsulo cha Strip, waya, Mitundu yonse ya zokumbira. |

| Kukonza | Kutembenuza Kugaya Kupera Kuboola mabowo akuya: kutalika kosapitirira mamita 9.8. |

| Mtundu wa ntchito | Chitsulo chozungulira: 1mm mpaka 2000mm Chitsulo chooneka ngati sikweya: 10mm mpaka 1000mm Chitsulo/pepala lachitsulo: 0.08mm mpaka 800mm M'lifupi: 10mm mpaka 1500mm Lenth: Tikhoza kupereka lenth iliyonse kutengera zomwe kasitomala akufuna. Kupangira: Ma shaft okhala ndi mbali/mapaipi/machubu/ma slugs/ma donuts/ma cubes/mawonekedwe ena Machubu: OD: φ4-410 mm, ndi makulidwe a khoma kuyambira 1-35 mm. |

| Chithandizo cha kutentha | Kubwezeretsa, Kuchepetsa, Kuchepetsa, Kulimbitsa ndi Kuchepetsa, Kukometsera, Kulimbitsa pamwamba, Kukonza Carburizing |

AWS E10015-D2 KUPANGIDWA KWA KHEMIKALI NDI KATUNDU WA KHEMIKANI:

| C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Cr | Ni |

| 0.15 | 0.6 | 1.65-2.0 | 0.03 | 0.03 | ≤0.9 | |

| Mo | Al | Cu | Nb | Ti | V | Ce |

| 0.25-0.45 | ||||||

| N | Co | Pb | B | Zina |

KATUNDU WA MAKANIKO:

| Katundu | Mikhalidwe | ||

| T (°C) | Chithandizo | ||

| Kuchulukana (×1000 kg/m3) | 7.7-8.03 | 25 |

|

| Chiŵerengero cha Poisson | 0.27-0.30 | 25 |

|

| Modulus Yotanuka (GPa) | 190-210 | 25 |

|

| Mphamvu Yokoka (Mpa) | 1158 | 25 | mafuta okazimitsidwa, odulidwa bwino, otenthedwa pa 425°C |

| Mphamvu Yopereka (Mpa) | 1034 | ||

| Kutalika (%) | 15 | ||

| Kuchepetsa Malo (%) | 53 | ||

| Kuuma (HB) | 335 | 25 | mafuta okazimitsidwa, odulidwa bwino, otenthedwa pa 425°C |

| Katundu | Mikhalidwe | ||

| T (°C) | Chithandizo | ||

| Kutentha kwa Matenthedwe (W/mK) | 42.7 | 100 | |

| Kutentha Kwapadera (J/kg-K) | 477 | 50-100 | |

KATUNDU WATHUNZI:

| Kuchuluka | Mtengo | Chigawo |

| Kukula kwa kutentha | 16 - 17 | e-6/K |

| Kutentha kwa matenthedwe | 16 - 16 | W/mK |

| Kutentha kwapadera | 500 - 500 | J/kg.K |

| Kutentha kosungunuka | 1370 - 1400 | °C |

| Kutentha kwa ntchito | 0 - 500 | °C |

| Kuchulukana | 8000 - 8000 | makilogalamu/m3 |

| Kusakhazikika | 0.7 - 0.7 | Ohm.mm2/m2 |

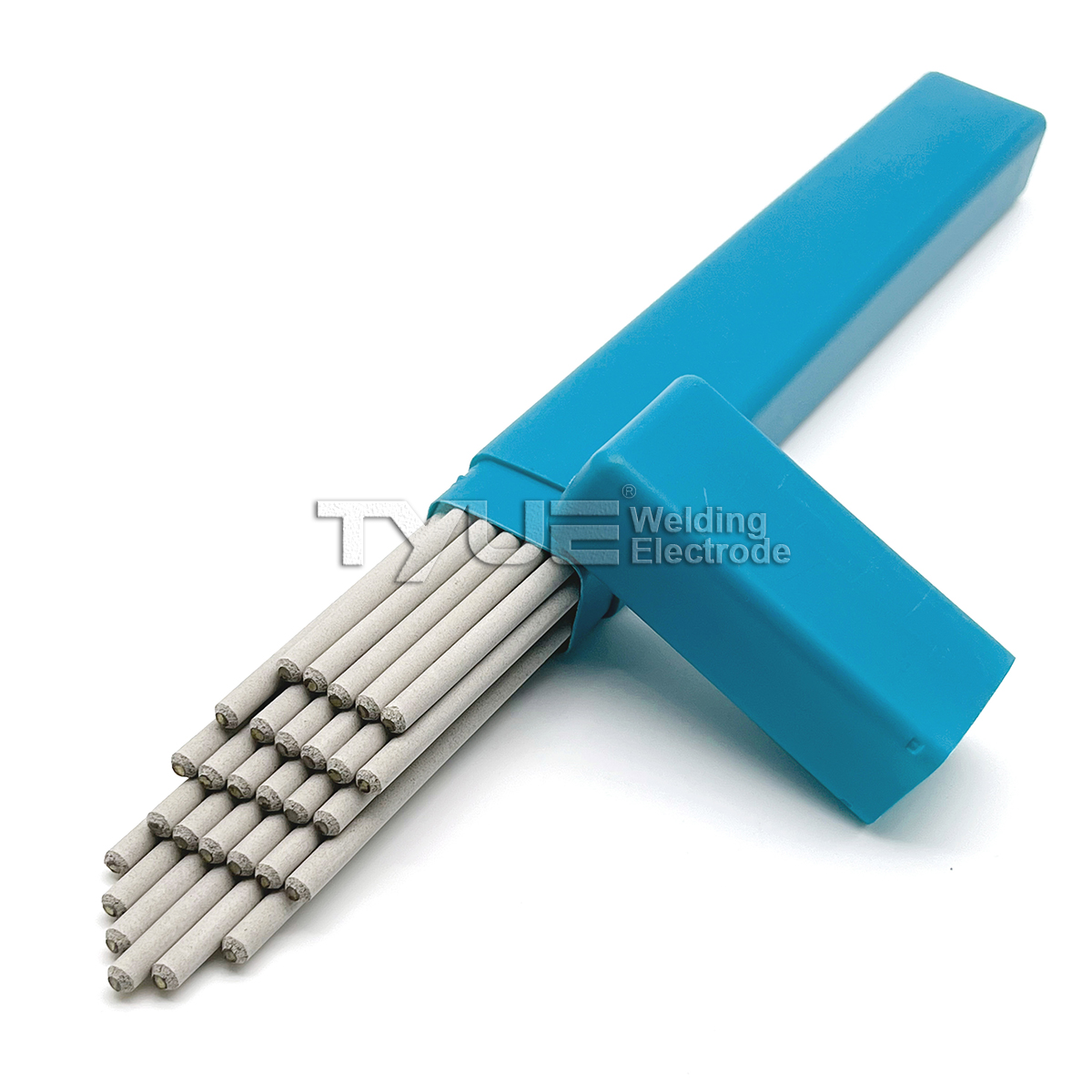

E7015-G Low Hydrogen Sodium Coating Welding Electrodes

KUFOTOKOZA:

Ndi ndodo yowotcherera yachitsulo yotsika kutentha yokhala ndi sodium hydrogen yochepa yokhala ndi nickel. Kuwotcherera komwe kuli konse kumatha kuchitika pogwiritsa ntchito kulumikizana kwa dc reverse. Chitsulo chowotcherera mu -80°C chimakhalabe ndi mphamvu yabwino.

NTCHITO:

Chopangidwa ndi chitsulo cha 1.5Ni cholumikizidwa ndi -80°C.

ZOPANGIDWA NDI CHITSULO CHA MANKHWALA OMWE ANAKHALAPO:

| C | Mn | Si | Ni | S | P | |

| Muyezo | ≤0.08 | ≤1.25 | ≤0.60 | ≥1.00 | ≤0.035 | ≤0.035 |

| Mayeso | 0.045 | 0.60 | 0.27 | 1.80 | 0.010 | 0.015 |

KUGWIRA NTCHITO KWA MANKHWALA A CHITSULO OMWE ANAGWIRITSA NTCHITO:

| Mphamvu Yokoka (MPa) | Mphamvu Yotulutsa (MPa) | Kutalika A (%) | -80°C Mtengo Wokhudza Mphamvu (J) | |

| Muyezo | ≥490 | ≥390 | ≥22 | ≥27 |

| Mayeso | 530 | 445 | 30 | 100 |

NJIRA YOFUNIKA (DC+):

| M'mimba mwake (mm) | 3.2 | 4.0 | 5.0 | |

| Utali (mm) | 350 | 400 | 400 | |

| Mphamvu (A) | 90-120 | 140-180 | 180-210 |

| E12015-G | Malinga ndi GB E8515-G Yogwirizana ndi AWS E12015-G |

Chiyambi: E12015-G ndi mtundu wa electrode yachitsulo champhamvu kwambiri yokhala ndi zokutira za natrium zochepa za hydrogen. DCRP (Direct Current Reversed Polarity). Kuwotcherera kwa malo onse.

Kugwiritsa Ntchito: Kumagwiritsidwa ntchito powotcherera nyumba zachitsulo zolimba kwambiri zokhala ndi mphamvu zochepa zokhala ndi mphamvu yokoka ya pafupifupi 830MPa.

Kapangidwe ka Mankhwala a Chitsulo Chosungidwa (%)

| Kapangidwe ka Mankhwala | C | Mn | Si | S | P | Mo |

| Mtengo Wotsimikizira | ≤0.15 | ≥1.00 | 0.4~0.8 | ≤0.035 | ≤0.035 | 0.60~1.20 |

| Zotsatira Zonse | ≤0.10 | ~1.50 | ≤0.70 | ≤0.020 | ≤0.020 | ~0.90 |

Katundu wa Makina a Chitsulo Chosungidwa

| Chinthu Choyesera | Rm(MPa) | ReL kapenaRp0.2(Mpa) | A(%) | KV2(J) |

| Mtengo Wotsimikizira | ≥830 | ≥740 | ≥12 | —(kutentha kwabwinobwino) |

| Zotsatira Zonse | 860~950 | ≥750 | 12~20 | ≥27 |

Kuchuluka kwa haidrojeni komwe kungasungunuke mu Chitsulo Chosungidwa: ≤5.0ml/100g (Chromatography)

Kuwunika kwa X-ray X-ray: ⅠDigiri

MALANGIZO:

1. Ma electrode ayenera kuphikidwa pansi pa 350-400℃ kwa ola limodzi musanawotchetse, kuyikidwa mu chidebe chotenthetsera ndikuyika nthawi yomweyo akafunika.

2. Madontho omwe ali pa cholumikizira ngati dzimbiri ayenera kuchotsedwa, ndipo cholumikiziracho chiyenera kutenthedwa mpaka madigiri 200 Celsius.

3. Chopoperacho chimatha kutenthedwa pansi pa 600-650℃ pambuyo powotcherera kuti athetse kupsinjika kwamkati.