ERNiFe-CI imagwiritsidwa ntchito powotcherera chitsulo chachitsulo.Chitsulo chodzaza ichi chimagwiritsidwa ntchito kwambiri kukuta zitsulo zachitsulo.Amagwiritsidwanso ntchito kukonza ma castings.Kutentha kwa preheat ndi interpass osachepera 175ºC (350ºF) kumalimbikitsidwa panthawi yowotcherera, popanda zomwe weld ndi madera omwe akhudzidwa ndi kutentha amatha kupanga ming'alu.

Ni 55 (kalasi la AWS silinatchulidwe) ndi waya wa Nickel 55%.Zomwe zili m'munsi mwa Nickel zimapangitsa kuti aloyiyi ikhale yotsika mtengo kuposa Ni 99. Ma weld deposits nthawi zambiri amatha kugwiritsa ntchito makina, koma pansi pa kusakanikirana kwakukulu, ma welds amatha kukhala ovuta komanso ovuta kupanga makina.Nthawi zambiri amagwiritsidwa ntchito pokonza ma castings okhala ndi zigawo zolemera kapena zonenepa.Poyerekeza ndi Ni 99, ma welds opangidwa ndi 55 Ni ndi amphamvu komanso ochulukirapo, komanso amalekerera phosphorous pakuponya.Ilinso ndi coefficient yocheperako yakukulira kuposa Ni 99, zomwe zimapangitsa kuti mizere yophatikizika ikhale yochepa.

KAPANGIZO WA CHEMICAL:

| NickelNi45.0-60.0% | IronFebalance | SiliconSimax 4.0% | ManganeseMn2.5% | CopperCu2.5% | CarbonCmax 2.0% | AluminiumAlmax 1.0% |

ZINTHU ZAMAKHALIDWE:

| Tensile mphamvu Rm (MPa) | Mphamvu zokolola Rp0.2 (MPa) | Elongation A% |

| min.393-579 (57-84 psi) | 296-434 (40-64 psi) | 6-13 |

MAFUNSO A PRODUCT:

| Zogulitsa | Diameter, mm | Utali, mm |

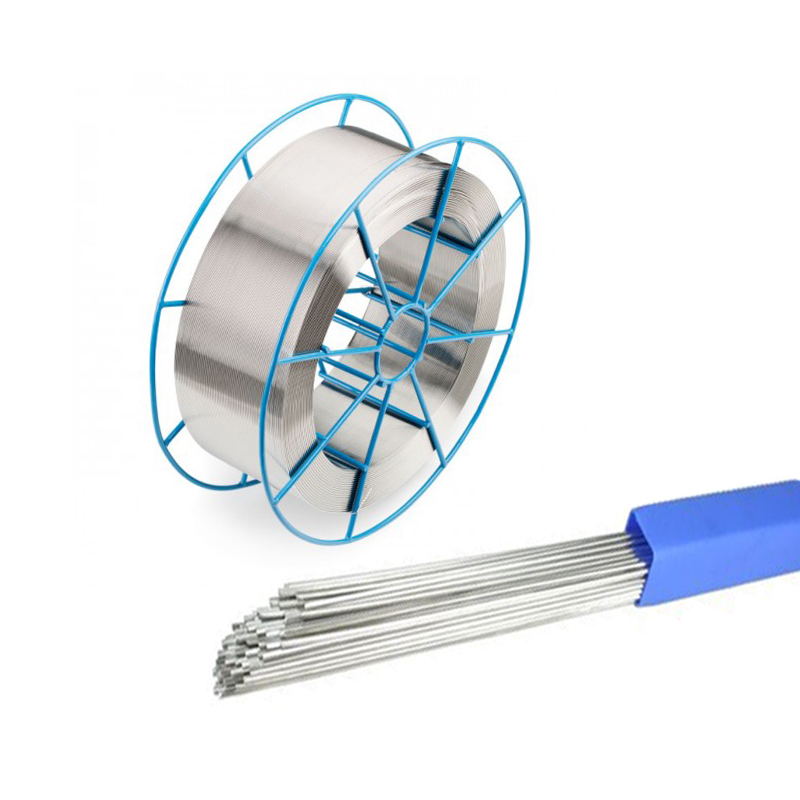

| Waya wa kuwotcherera kwa MIG/GMAW | 0.8, 1.0, 1.2, 1.6, 2.0, 2.4, 2.5, 3.2 | - |

| Ndodo za kuwotcherera kwa TIG/GTAW | 2.0, 2.5, 3.2, 4.0, 5.0 | 915-1000 |

| Waya wowotcherera wa SAW | 2.0, 2.4, 3.2, 4.0, 5.0 | - |

| Electrode core waya | 2.0, 2.5, 3.20, 3.25, 4.0, 5.0 | 250, 300, 350, 400, 450, 500 |

Binary Nickel-Iron (Ni-Fe) ndi Ni-Fe) ndi Ni-based complex kuwotcherera aloyi amaperekedwa mu kuwotcherera ndodo ndi mawaya muyezo utali kapena utali mpaka pempho ogula.Pazinthu zogwirira ntchito wamba, zida za mankhwala zimapezeka m'mitundu yosiyanasiyana ya Ni malinga ndi miyezo yaku America ndi ku Europe.